In the October 1958 edition of the Veteran & Vintage magazine, an article from a correspondent Adrian Secker mentions his finding of two supercharged Amilcars in East Berlin just after the war. "They were too far gone for restoration" he writes. In 1960, the Amilcar register was then approached by a Swiss journalist, Mr Heinz-Ulrich Wiesselmann, in East Berlin offering an Amilcar C6 (alegely the car above) together with the remains of a second car (alegely C6 Amilcar - 11023 ). The C6 chassis number 11032, was a complete car when discovered . Together with a spare chassis, 11023, the Amilcar was eventually smuggled out bit by bit into Switzerland.

Engine 90016 used during the 500mile race at Brooklands was rescued from France whilst being used for powerboat racing.

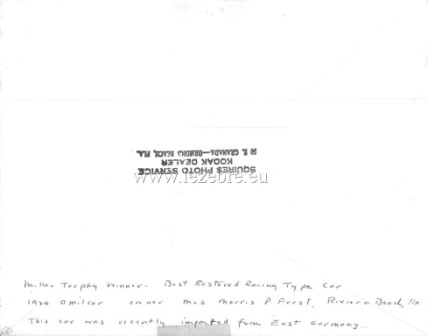

Both were purchased by a Mr and Mrs Frost of Florida, USA, who restored 11032 and sold the spare chassis 11023 to Desmond Peacock in the UK, whom they met while in England and who expressed an interest and subsequently bought and imported the second car in bits. He pooled his resources with a friend Guy Weightman who had further missing parts bought directly from the Amilcar factory in 1930 and together they initially rebuilt the car without registering it for road use before selling the car to Keith Bowley in the 1980's. (allegedly C6 Amilcar - 11023)

The Amilcar register then received a letter from Mr Frost from the USA indicating that he had purchased the cars and restored one of them (allegedly the car above).

11023 was later rebuilt as a complete car and featured in The Automobile (January 1997 edition).

Maurice Frost ran 11032 for some time as a road car having fitted an accumulator box and starter motor. After some years the engine block cracked and a repair proved impossible, so Frost sold the Amilcar to a small motor museum. 11032 was later purchased from the museum by a British motor dealer, Mr Dan Margulies, who sold it on to a German client called Zinkle. Mr Zinkle delivered the car to Tomkins Engineering in Essex for rebuilding, and a subsequent deal involved Tomkins taking the Amilcar into stock. Bob Graves purchased the partially rebuilt car from Tomkins in 1982.

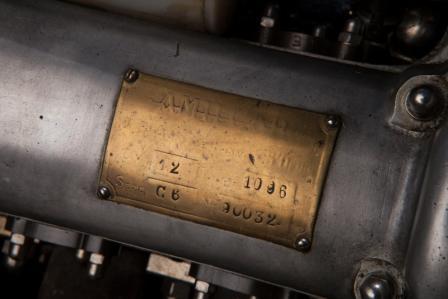

This Amilcar C6 was purchased as a complete car with matching part numbers except for the rear axle. Amilcar manufactured cars from kits of components, all stamped with the same number as the engine, though the chassis were never stamped during the 1920s. A serial number comprising the engine number with the first two digits substituted for '11' would then be allocated to each completed car. However, this C6's obviously very original body had no trace of any number, so it must obviously have been on a plaque. This car would have been 11032.

This chassis has the engine number stamped on the dumb-irons but its lettering is different from all other stampings and was probably done for customs purposes to facilitate crossing boarders. The front axle assembly is stamped and the entire original assembly of stub axles, track rods and steering arms is in place. The steering box is original and correctly numbered. The radiator shell is original but the matrix has been renewed using the original honeycomb.

Plated 11032, the damaged engine was beyond use. New iron castings were commissioned to replace the original block and cylinder head, and were made by Grainger & Worrall Ltd, suppliers of iron castings to Cosworth. At the same time the opportunity was taken to provide an outlet for a modern full-flow oil filter. Many original components were used in the rebuilt engine: camshafts, magneto, water pump, timing gears, etc. The remanufactured engine is in a sense more 'original' than before, as machining has been done accurately to conform to the original Amilcar drawings, unlike the often sub-standard factory castings.

Cylinder head gasket failure was a common problem with these Amilcar engines, and Bob Graves's solution was to commission special seals that fit into concentric slots machined in the block around each cylinder. The new cylinder head casting, thicker in crucial areas, was machined to take modern 10mm spark plugs. Machining was carried out on the jig used for the very first Cosworth DFV heads. Fixing thread sizes were changed wherever it was thought they would improve reliability. Later cylinder head castings were thicker under the inlet ports, resulting in a stronger structure and superior port shape. Improvements were made to the oil and water pumps, and the clutch relined with a modern material, the latter necessitating a thicker pressure plate and stronger springs.

The gearbox and torque tube are correctly numbered but the gearbox casing was cracked and attempts at welding were aborted because of its porosity. A new casing was cast from the original in LM25 aluminium alloy, and the lengthy standard gear lever replaced with a remote linkage.

The original body has been retained and looks very good externally but is in fact full of filler, while its steel frame is deeply rusted. In a letter on file, Bob Graves remarks that C6 bodies were obviously hand built when the cars were ordered, as he had never seen two identical shapes. The current body was made from templates of the original. Construction is based on steel angle frame exactly as the original. The oil tank, normally carried between the front dumb-irons, has been moved to the engine bay firewall.

The brake back plates (the front ones are used to reinforce the steering arms) have been replaced because, like all C6 aluminium castings, they are highly suspect. Those fitted currently are replicas in heat-treated LM25.

The front dampers are built to Amilcar pattern but are of larger diameter and have additional friction plates. The rears are 1920s Rotoflex concealed behind the body because they were considered somewhat ugly. Road springs are the originals complete with the French maker's name. The rear ones are 'keyed' together, an Amilcar patent to supposedly provide lateral stability. Additional location is provided by a Panhard rod.

The rear axle carries the number '90016'. That is the number of the engine in the other C6 referred to above, which has this car's original axle, stamped 11032. These axles were obviously interchanged while in the ownership of Mr and Mrs Frost in the USA.

Although just about acceptable when the car was purchased, the brakes quickly revealed their shortcomings and were progressively upgraded by Bob, their development taking a number of years. A mechanical balance bar has been installed to make the rear brakes more effective; some of the cables have been replaced with rods; and the front brakes have been converted to twin-leading-shoe operation.

In another letter on file, Bob states that the only power output enhancement on this car is the use of a standard Amilcar exhaust camshaft in the inlet position plus using steel tubes in the inlet ports to reduce their diameter and thus increase gas velocity and fuel atomisation. While satisfactory for running on petrol, the stock induction pipe was found quite unsuitable for alcohol fuel. Bob fitted a single feed from the supercharger to a primary pipe, feeding in two places into a secondary pipe, which in turn feeds the individual inlet ports. Experimentation revealed that alternative inlet and exhaust systems gave significant power increases but their use would have involved altering the bodywork and thus was rejected. Modifications to the fuel system included a new custom-made mechanical air pump and a smaller-capacity tank.

One of the more surprising discoveries was that the standard rev counter lagged well behind the crankshaft - blipping the engine to an indicated 4,000rpm actually revved the motor to 7,000! Bob cured this problem by using a modern Stack digital rev counter disguised with an Amilcar-style dial and bezel.

Bob estimated that manufacturing a C6 engine from scratch took 2,500 hours, and given the amount of care and attention to detail that this seems to have involved, that figure may well have been an underestimate. The development history of his Amilcars is recorded in detail in a fascinating 17-page document on file (perusal highly recommended). The highest power output quoted therein is 150bhp at the crankshaft, and the Graves Amilcar C6s are recognised as being the fastest in existence, dramatically quicker than the works cars were in period.

11032 was raced extensively by Bob Graves in VSCC

events and is pictured competing at Silverstone in 1994 and 1998,

and the Brooklands Sprint in '98. The car is offered for sale by the

Graves family and comes with a copy of the VSCC 'Buff Form'.

This Amilcar is to be offered with the following spares: 1 x Oil

Tank 2 x Brake Drums 1 x Gearbox Top and Lever 4 x Halfshafts 3 x

Camshafts 2 x Cam-Covers 1 x Cylinder Head 2 x Magneto's 1 x

Carburettor 2 x Wheel Rims 1 x Crankshaft Other Assorted Parts

Transaction:

Auction / Vente aux encheres:

-

RM Sotheby's

-

London 2023

-

Sold for 161,000 BPD

-

-

GOODWOOD REVIVAL

-

12 Sep 2015, 13:30 BST Lot 348

-

1927 AMILCAR C6

-

Chassis no. 11032 Engine no. 90032

-

Est: £250,000 - 300,000 / US$ 330,000 - 400,000

-

CHICHESTER, GOODWOOD

-

Chassis / moteur / engines / numbers / numeros

Chassis no. 11032

Engine no. 90032

- 1982: Bob Grave

- Mr Ziekle

- Dan Margulies

- Small motor museum

- Mr Frost (Florida)

- East Berlin

- Production: 1927